When purchasing a bread clip machine, it's important to evaluate several factors to ensure that the machine meets your production needs and offers long-term reliability. Here’s a checklist of key considerations for the bread bag clip machine:

1. Production Volume: Assess your current and future production volumes. Choose a bread bag clip machine that can handle your expected output without excessive wear and tear. Consider the speed of the bread bag clip machine and whether it aligns with your production line’s throughput.

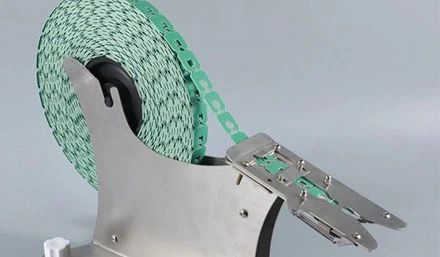

2. Type of Products: Determine the types of bags and products the bread bag clip machine will be used for. Bread clip machines can vary in their compatibility with different bag materials and sizes. Ensure the bread bag clip machine is suitable for the specific types of bags (e.g., plastic, paper) and closures you use.

3. Machine Flexibility: Look for bread bag clip machines that offer adjustable settings to accommodate various bag sizes and clip types. This flexibility allows you to adapt the bread bag clip machine for different products and packaging designs, which can be particularly valuable as your product range expands.

4. Ease of Use: Consider how user-friendly the bread bag clip machine is. Look for features like touch screen controls, easy setup, and clear instructions. A user-friendly bread bag clip machine can reduce training time and increase productivity.

5. Maintenance and Durability: Check the bread bag clip machine’s build quality and inquire about maintenance requirements. A durable bread bag clip machine with easily accessible parts for routine maintenance will ensure longer service life and less downtime.

6. Technical Support and Warranty: Evaluate the bread sealing clip manufacturer’s customer service and technical support. Good after-sales support can be crucial for troubleshooting and ensuring continuous operation. Also, check the warranty period and what it covers.

7. Integration with Existing Systems: If you have an existing production line, assess how easily the new bread bag clip machine can be integrated. Compatibility with your current setup can influence installation costs and operational efficiency.

8. Cost: Beyond the initial purchase price, consider the total cost of ownership, which includes maintenance, parts, and potential downtime. A cheaper bread bag clip machine might cost more in the long run if it requires frequent repairs or replacement.

9. Reviews and Reputation: Research the manufacturer’s reputation and read customer reviews. Learning from the experiences of other users can provide insights into the reliability and performance of the bread bag clip machines.

By carefully considering these factors, you can choose a bread clip machine that effectively meets your needs and supports efficient, reliable packaging operations.