When choosing a twist tying machine, there are several key factors to consider to ensure that the equipment meets your specific needs and enhances your operational efficiency. Here are the crucial aspects to evaluate:

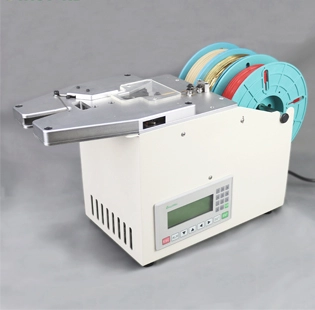

1. Production Volume: Assess the volume of items that need to be tied daily. High-volume environments will require a more robust machine capable of handling continuous operation without frequent maintenance.

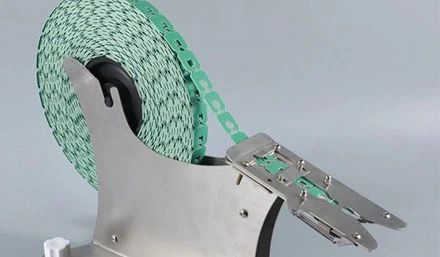

2. Type of Products: Consider the type of products that the machine will be used to tie. Different machines may handle various materials and sizes, from delicate bakery goods to sturdy hardware items. Ensure the machine is suitable for your product's material and sensitivity.

3. Twist Tie Material: Check what types of packaging twist ties materials the machine can use (e.g., paper-covered, plastic-covered, or metallic ties). The choice of material can impact both the appearance and the durability of the seal.

4. Adjustability: Look for a machine that offers adjustable settings for tie tightness, length, and the number of twists. Flexibility in these settings allows you to customize the operation according to different product requirements.

5. Speed: Consider the speed at which the machine operates. A faster machine can significantly increase productivity but may come at a higher cost. Ensure the speed matches your production needs without sacrificing the quality of the tying.

6. Ease of Operation and Maintenance: Evaluate how user-friendly and maintenance-friendly the machine is. Check for features such as easy access for reloading materials, simple controls for operators, and straightforward procedures for routine maintenance.

7. Integration Capability: If you're incorporating the twist tying machine into an existing production line, it's essential to ensure that it can integrate seamlessly with other equipment. Check compatibility in terms of speed, height, and operational logistics.

8. Durability and Reliability: Research the build quality and reliability of different models and twist ties manufacturers. A durable machine that can operate consistently under your specific conditions is a worthwhile investment.

9. Support and Warranty: Consider the level of customer support and warranty provided by the manufacturer. Good after-sales support can minimize downtime and ensure that any issues are promptly resolved.

By carefully assessing these factors, you can select a twist tying machine that optimally suits your operational needs and contributes to the efficiency and quality of your production process.